Leatherneck Precision Machine is a Service-Disabled Veteran-Owned Small Business that specializes in precision machined components for the aerospace, defense, medical, dental, injection molding and other commercial industries that need precision machined parts for their product lines. Sometimes people’s lives depend on special machine parts, such as aircraft structures, automobiles, and human-rated spacecrafts, and Leatherneck is an AS9100D- and ISO9001-certified company able to do that technical work. He also has SDVOSB and SDVBE certifications (for small disadvantaged veteran-owned small business).

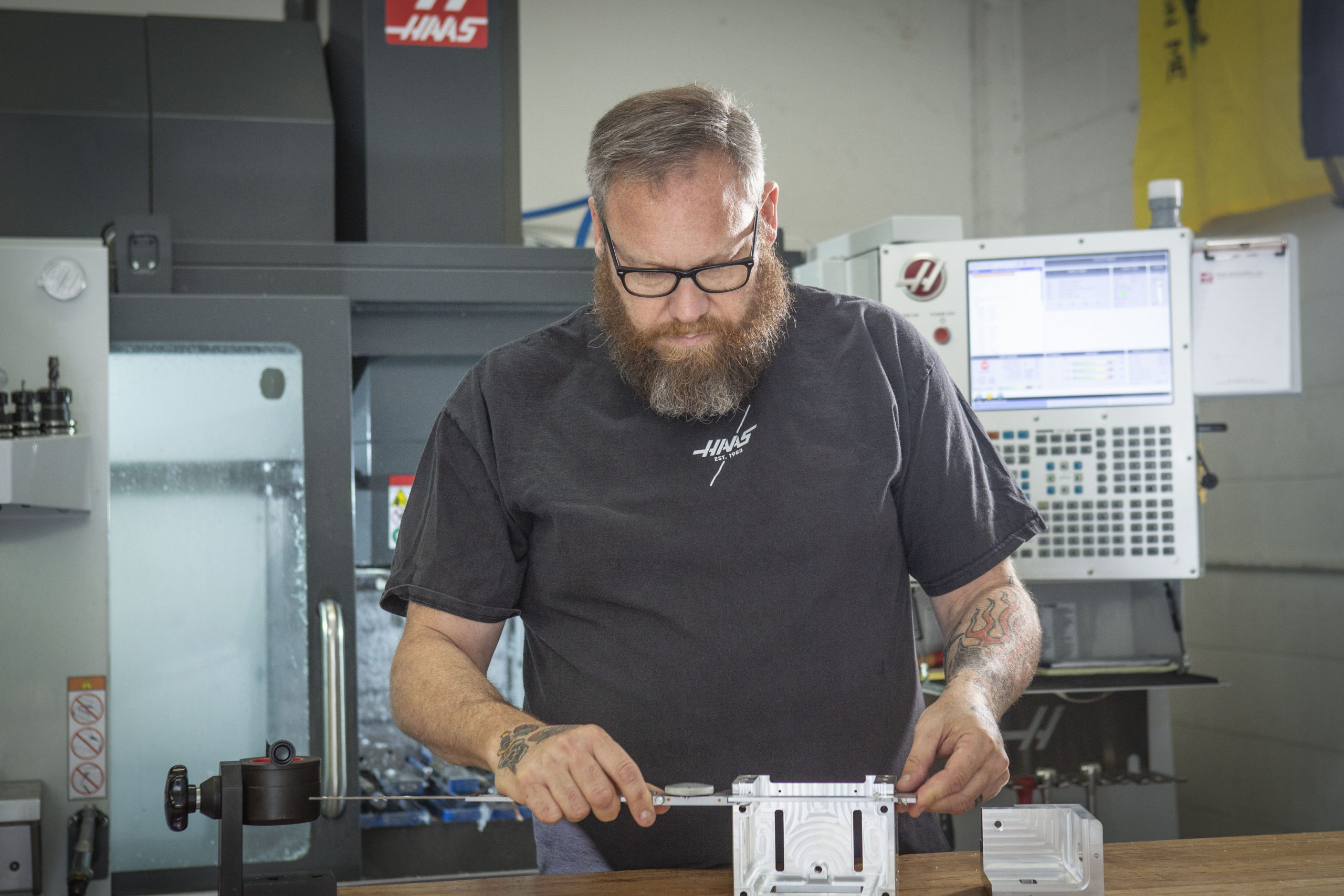

Anthony Marshall, Owner and President, is a US Marine Veteran who served in Somalia in 1994. After leaving the Service he became a CNC Machinist working at companies such as Lockheed Martin, Space X and several other tier 2 aerospace suppliers. He has worked on several high-profile projects like the Dragon 1 & 2 spacecrafts, Falcon 9 and Falcon heavy rockets, The Orion Spacecraft, Mars 2020 spacecraft, F35, F22, C130, 767, Delta and Atlas rockets. Anthony started Leatherneck Precision Machine in October 2017 to help Veterans transition from the military and learn a valuable skill set that will lead to significant employment for the rest of their lives.

Leatherneck’s first CNC milling machine was delivered in late July 2018 to their facility in Englewood. Anthony worked with a local nonprofit lender to fund a second CNC milling machine added in November 2019. This machine allows the company to do twice the work. “The SBDC has helped with my business education from the beginning, including, small business events, half-day workshops and one-on-one consulting. The Aurora-South Metro SBDC are Rock Stars for the aspiring entrepreneur, a very valuable resource for the business community.” The Small Manufacturers AdvantEDGE program proved valuable to help get his space ready for business. In fact, Leatherneck Precision Machine was host to the City of Englewood’s Manufacturing Day celebration in 2019. The industries that are integral to the company’s success are booming. As a result, expansion plans are to add a CNC lathe and a Coordinate Measuring Machine in 2020, inspection equipment as needed, as well as hire one or two employees to help with the work load. Eventually, Anthony would like to grow large enough, doubling or tripling in size in the next year, by buying his own building and hiring wounded veterans—and yet stay small enough to stay in touch with his customers and employees.